Quick Product Menu

Pneumatic Inking Systems

Xandex Pneumatic Inkers incorporate the convenience of DieMark disposable ink cartridges with the reliability of a microprocessor-controlled pneumatic dispensing system for the ultimate inking solution. Ink dots are deposited via pneumatic actuation of the inker shuttle mechanism and a simultaneous pulse of air into the cartridge reservoir. There is no filament and no direct contact with the wafer surface. Dot size is determined by cartridge type and air pulse duration. Adjust the controller setting to achieve a range of dot sizes from a single cartridge. For a comparison of Xandex Pneumatic and Electric Inking Systems, go to Selecting Xandex Inking Systems.

Drawing Prefix Key: EG = Electroglas Prober Application: KLA = KLA Prober Application: TSK = Tokyo Semitsu Prober Application: TEL = Tokyo Electron Prober Application: PWS = Pacific Western Systems Application: LT = Laser Trimmer Application

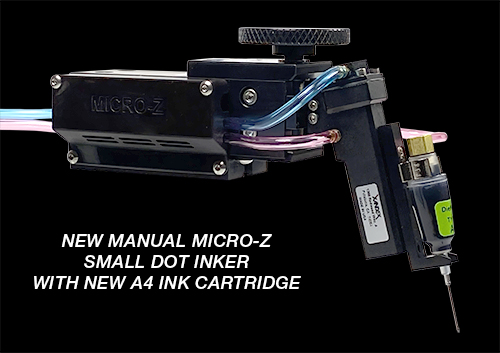

NEW X7110 Manual & X7120 Motorized Micro-Z

Manual or Motorized Micro-Z adjustment with new design features enable fast, precise setup for high volume, small ink dot production.

Manual or Motorized Micro-Z adjustment with new design features enable fast, precise setup for high volume, small ink dot production.

- NEW Precision Shuttle design for repeatable small dot production

- Manual Inker: 20 % increase in Manual Z-Stage ajustment resolution

- Motorized Inker: Push button Z adjustment in 0.0005" or 0.00005" increments

- Variable dot size – 3 mil to 50 mil dependent on cartridge and ink type

- Rigid Inker Body design to reduce vibration

- Designed for use with the NEW A4 Small Dot Ink Cartridge

- NEW Pneumatic Controller designed for small dot inking

- Programmable dot counter with audible alarm

- Models for EG, KLA, TSK, TEL and other wafer probing equipment

Learn More

Dimensional Drawings and Product Manual Links

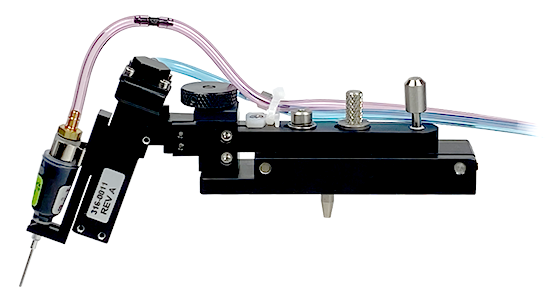

X1000 Series

Our original pneumatic dispensing system for cabled probing and off-line inking

Our original pneumatic dispensing system for cabled probing and off-line inking

- NEW Precision Shuttle for improved small dot placement

- NEW 20 % increase in Z-Stage ajustment resolution

- Flip-up manipulator for quick cartridge changeout

- Manual Z adjustment

- Joystick for fine X,Y positioning

- Models for EG, TSK probers

Dimensional Drawings

X5100

Designed for the EG Horizon Series probers.

Designed for the EG Horizon Series probers.

- Mounts in the prober's optical bridge (4080-4090)

- High speed off-line and post-probe inking

- Dot range of 15-50 mils, depending on cartridge size

Outline Drawings

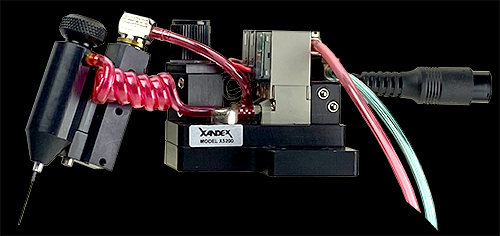

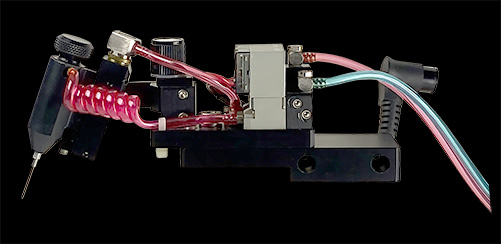

X5200 and X 5210 for TEL probers

Designed specifically for the TEL P8 prober

Designed specifically for the TEL P8 prober

- Variable dot size; 15-40 mils

- Remote valve increases accuracy and repeatability.

- High speed ink dot deposition – up to 12 dots per second

- Models available for P8 Bridge (X5210) or SACC arm (X5200)installation

Outline Drawings

X901 Handheld DieMarker

Hand held pneumatic inker for manual ink dot placement.

Hand held pneumatic inker for manual ink dot placement.

- The ergonomic X901 inker is designed to fit comfortably in the user’s hand

- Allows placement of ink dots using a foot activated switch.

- Enables users to utilize the exact same ink cartridge as in the wafer sort operation.

Dimensional Drawings

Pneumatic Controller CE & UKCA Declerations of Conformity

Xandex DieMark® Declarations of Conformity to CE and UKCA are available as a single PDF file. Click HERE to view/download.