Quick Product Menu

Micro-Z Small Dot Inking Systems

MICRO-Z INKING SYSTEM | MICRO-Z INKER MODELS | MICRO-Z CONTROLLER

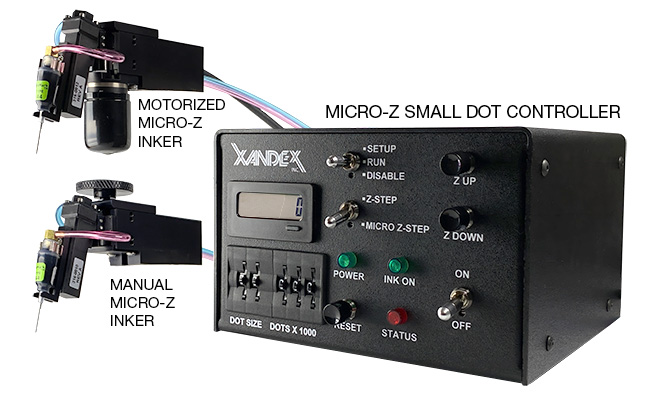

NEW Micro-Z Small Dot Pneumatic Inking Systems

Micro-Z Small Dot Inking Systems

The NEW DieMark Micro-Z Small Dot Pneumatic Inking Systems are the next generation of small dot die marking systems from Xandex. The Manual and Motorized Micro-z inker assemblies and the Micro-Z Pneumatic Controller incorporate new design improvements that enable 5 mil and smaller ink dot production with accurate dot placement, consistent dot geometry and excellent repeatibility.

Designed specifically for use with the NEW DieMark A4 Pneumatic Ink Cartridge, the Micro-Z Inking Systems and A4 Ink Cartridge are THE solution to mark small die that shrink at each development node.

Learn more about the NEW A4 Small Dot Pneumatic Ink Cartridge!

MICRO-Z INKING SYSTEM | MICRO-Z INKER MODELS | MICRO-Z CONTROLLER

Micro-Z Manual and Motorized Inker Models

The Xandex design and engineering team re-examined the existing inker models and identified areas for improvement. The Micro-Z Inker design changes focus on features specific to repeatable, reliable small (5 mil and smaller) ink dot production.

New Precision Shuttle

A new Precision pneumatic shuttle design that reduces friction between moving parts and eliminates potential vibration related parts movement for more accurate, repeatable dot placement. Designed for the Micro-Z inker, the new Precision Shuttle is such a great performance improvement it is now standard equipment on the X1100 Series and the X1400 Series DieMark Pneumatic Inking Systems.

New Rigid-body Design

The Manual and Motorized Micro-Z Models also include a rigid-body re-design that eliminates multiple points of movement compared to previous pneumatic inker models. By eliminating vibration induced movement in the inker body, ink dot placement accuracy and repeatability are improved.

Manual Micro-Z Inker: Z Stage Resolution

The Manual Micro-Z Model inker's Z height adjustment system is 20% more accurate than the adjustment available on previous manual DieMark inker models. Accuracy in Z adjustment is critical in obtaining uniform small ink dots.

Motorized Micro-Z Inker: Z Stage Resolution

The Motorized Micro-Z is available to combine extremely accurate Z adjustment with the ease of push button controls. The Motorized Micro-Z inker provides Z adjustment of 0.00005 inches per actuation in Micro-Z mode. Accuracy in Z adjustment is critical in obtaining uniform small ink dots.

MICRO-Z INKING SYSTEM | MICRO-Z INKER MODELS | MICRO-Z CONTROLLER

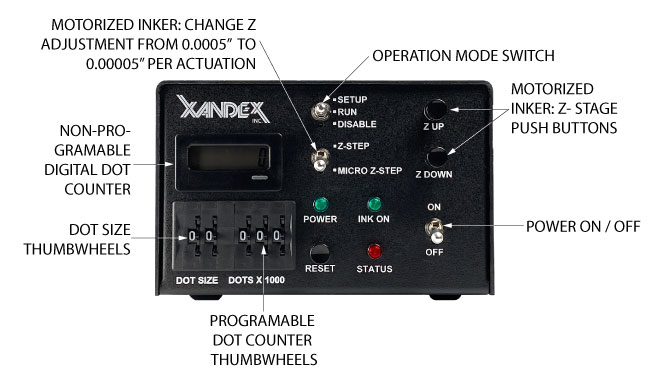

Micro-Z Pneumatic Controller

Micro-Z Small Dot Pneumatic Controller

The NEW DieMark Micro-Z Small Dot Pneumatic Controller is designed to work with both the Manual and Motorized Micro-Z Inkers along with the NEW A4 Ink Cartrtidge to produce small, 3-5mil ink dots.

The NEW DieMark Micro-Z Small Dot Pneumatic Controller is designed to work with both the Manual and Motorized Micro-Z Inkers along with the NEW A4 Ink Cartrtidge to produce small, 3-5mil ink dots.

The Micro-Z Pneumatic Controller underwent the same evaluation and re-design as the Inker Assemblies in order to maximize small dot performance, and includes the following improvements.

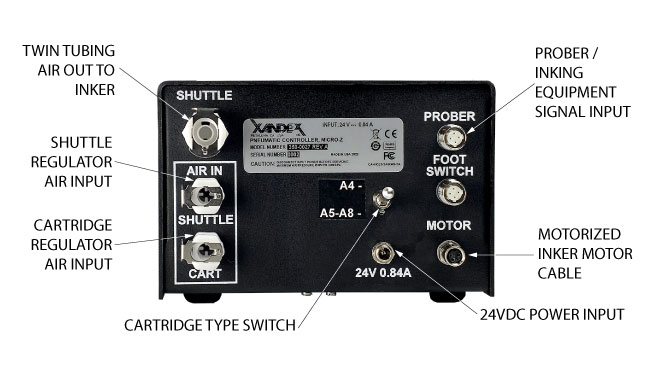

Isolated Shuttle and Cartridge Valve Air Supplies

In previous Pneumatic Controllers, the Shuttle Valve Cartridge Valve shared a single air supply input. In order to eliminate any minor pressure changes that may affect the air input to the Shuttle and Cartridge valves the Micro-Z controller has two (2) regulated air inputs. Each is dedicated to either the Cartridge Valve or the Shuttle Valve to ensure the air supply to each valve and its output is unaffected by the other's operation.

New Digital Cartridge Valve

The Cartridge Valve that supplies air to the ink cartridge to place an ink dot has been replaced with a new digital valve that can be controlled more accurately than the valve used in previous controller models.

New Controller Firmware

The controller has new firmware which controls the "puff pulse" sent to the ink cartridge depending on the position of the toggle switch on the back of the controller. For small dot production using the A4 ink cartridge, place the toggle switch in "A4" position. For other cartridge types, use the "A5-A8" position.

Z-Step and Micro-Z Step

The Motorized Micro-Z inker has a motor driven Z-stage adjustment. When this controller switch is in Z-Step mode the shuttle is adjusted up or down in 0.0005 inch increments with each up or down button press. When in Micro-Z Step mode, the shuttle moves in 0.00005 inch steps up or down with each button press. This allows extremely accurate positioning of the cartridge tip to the wafer surface, which is key to placing uniform, repeatable, small ink dots.